money. If your bike doesn’t work, so you can’t go out riding. If a factory’s bikes or trikes break, they have a real problem.”

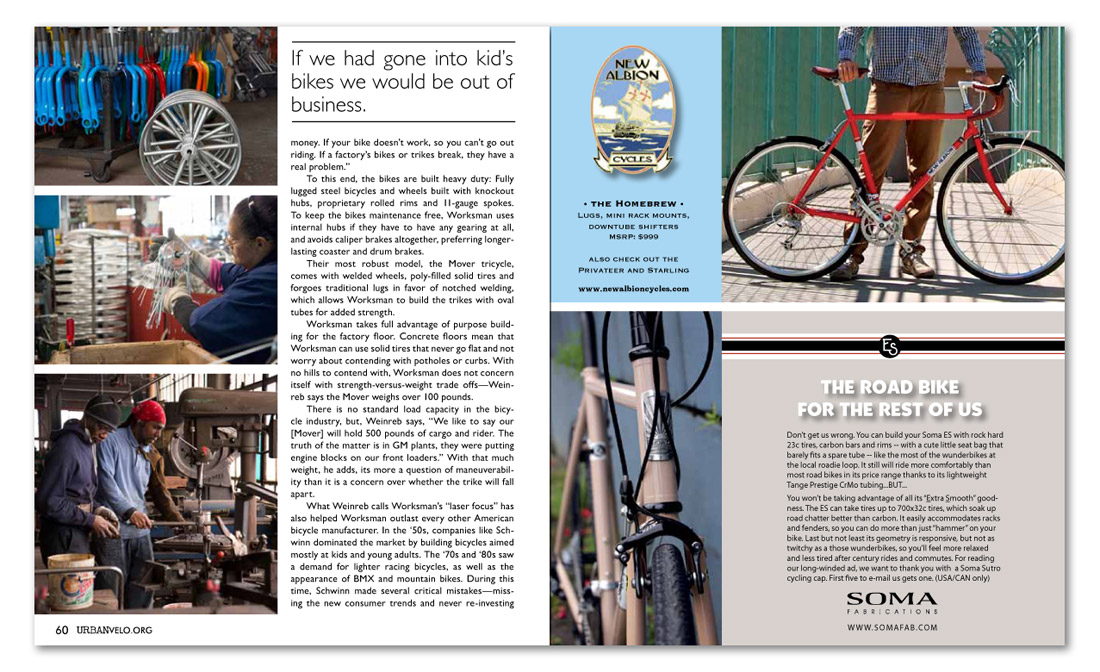

To this end, the bikes are built heavy duty: Fully lugged steel bicycles and wheels built with knockout hubs, proprietary rolled rims and 11-gauge spokes. To keep the bikes maintenance free, Worksman uses internal hubs if they have to have any gearing at all, and avoids caliper brakes altogether, preferring longer-lasting coaster and drum brakes.

Their most robust model, the Mover tricycle, comes with welded wheels, poly-filled solid tires and forgoes traditional lugs in favor of notched welding, which allows Worksman to build the trikes with oval tubes for added strength.

Worksman takes full advantage of purpose building for the factory floor. Concrete floors mean that Worksman can use solid tires that never go flat and not worry about contending with potholes or curbs. With no hills to contend with, Worksman does not concern itself with strength-versus-weight trade offs—Weinreb says the Mover weighs over 100 pounds.

There is no standard load capacity in the bicycle industry, but, Weinreb says, “We like to say our [Mover] will hold 500 pounds of cargo and rider. The truth of the matter is in GM plants, they were putting engine blocks on our front loaders.” With that much weight, he adds, its more a question of maneuverability than it is a concern over whether the trike will fall apart.

What Weinreb calls Worksman’s “laser focus” has also helped Worksman outlast every other American bicycle manufacturer. In the ‘50s, companies like Schwinn dominated the market by building bicycles aimed mostly at kids and young adults. The ‘70s and ‘80s saw a demand for lighter racing bicycles, as well as the appearance of BMX and mountain bikes. During this time, Schwinn made several critical mistakes—missing the new consumer trends and never re-investing

Soma

New Albion